What are the reasons for noise when large girth gear working?

19 Dec 2023 UTC+8Views:

When purchasing large gears, customers will talk about noise when communicating with manufacturers. This is mainly because in large girth gear work, various noise will appear, which makes people feel boring. In order to improve the market share, when the steel casting plant is designed and produced, it will take into account this problem, thereby increasing the user's experience of the customer, while increasing the brand's popularity.

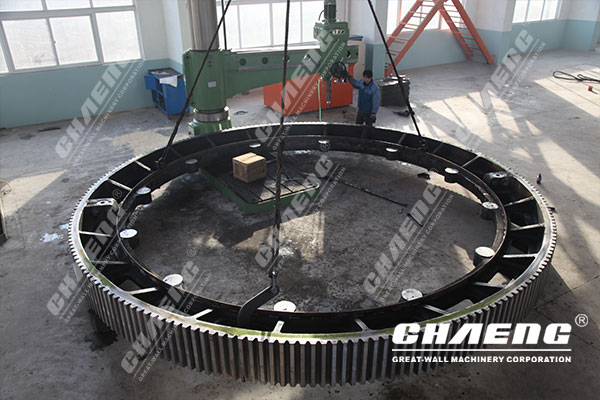

Large girth gears are important transmission parts of kiln and mill accessories in mines. Its quality will directly affect the stability and safety of kiln and grinding equipment. When the large -scale casting steel plant is produced, it mainly improves the precision of the large girth gear. From the data, we learned that the accuracy of the girth gear is related to the level of noise and a side gap. At the same time, in the process of production, the tooth shape error and the spacing of the tooth shape are one of the factors that affect the noise, and it is one of the reasons why girth gear accuracy cannot guarantee.

After receiving the drawings from the customer, the large -scale casting steel plant will communicate with the customer in detail, combined with actual use problems, and customize a suitable casting solution for customers to solve the noise of the large girth gear during operation. question. At the end of the year, there are many maintenance of cement plants and mining stars. There are many large tooth fengs that need to be replaced. If you need to purchase a large girth gear or other spare parts, please send the drawings to my mailbox contact@chaeng.co. we will provide you with customized services and quotations