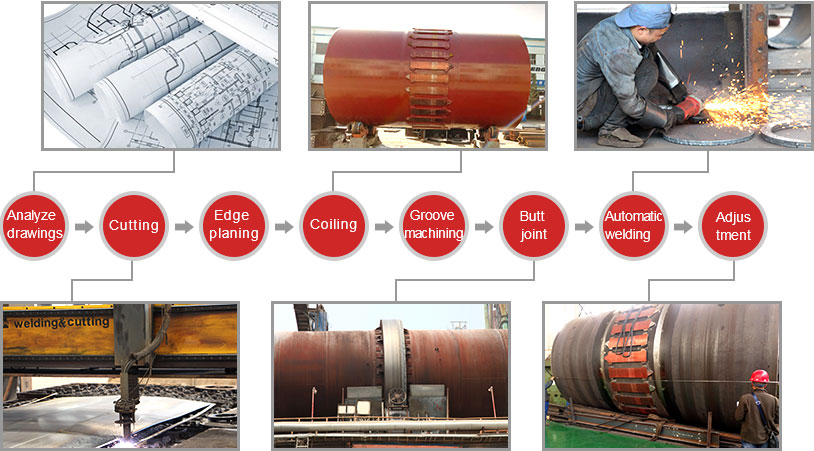

Rotary kiln shell fabrication process and materials

02 Nov 2021 UTC+8Views:

The rotary kiln shell is one of the main components of the rotary kiln, and it is a long cylindrical tube made of steel plate. Q235 and Q345 are generally selected as the rotary kiln shell material.

Due to transportation reasons, the rotary kiln is composed of shell segments. Because the outer circle of the kiln cylinder is not processed, the perpendicularity of the end face to the center of rotation cannot be directly measured. In the process design, the perpendicularity of the end face is converted into parallelism and the coincidence of the axes at both ends according to the structure of the cylinder.

CHAENG designs specific manufacturing and welding processes of single-segment shells according to the detailed requirements of the drawings. After the assembly and welding of the cylinder, perform the post-weld treatment, including non-destructive testing, post-weld heat treatment, and pressure resistance test to ensure the high quality of the kiln shell.

CHAENG has strong casting and machining capabilities, and large annual output. We strictly follow the level-2 national inspection standard and implement non-destructive testing systems to ensure the quality of steel castings. CHAENG has close cooperation with many companies of various industries, supplying them with spare parts with good performance to improve the practical effect of the equipment and extend the service life of the equipment. CHAENG has won the high praise of customers!