Customized large steel casting slag pot

22 Mar 2018 UTC+8Views:

In the March, a batch of slag pots made by CHAENG were sent to there users in Ningbo, Anyang, Wuhan, etc.

CHAENG is experienced manufacturer to supply large steel casting slag pot customized according to users’ drawings and demands. By now, CHAENG slag pots have been sold to the more than 50 countries and regions like United States, Mexico, Brazil, India, South Korea, Japan, Russia, and so on.

In order to offer slag pots to customer satisfaction, CHAENG:

- communicates fully with customers to make specific production plan

- numerically simulate the casting process by CAE software

- selects appropriate wooden mold for modeling design

- strictly control every procedure of mold, modelling, casting and testing

- strictly follows the national lever-2 detection standards, and executes 360° all-round nondestructive testing system

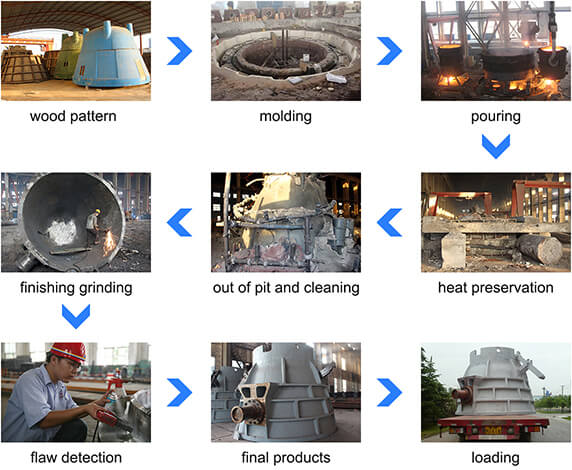

Process of CHAENG steel casting slag pot:

Advantages of CHAENG steel casting slag pot:

- The key parts of CHAENG slag pot can reach level-2 testing standards of GB7233-2007

- Long service life better than the traditional casting slag pot

- Customized according to customers’ drawing and demands.

- CHAENG has successfully cooperated with Shanghai Baosteel, Mittal Group, TaTa Group.

Welcome to consult CHAENG for details and quotation of large steel castings!