CHAENG: experienced large cast steel girth gear manufacturer in China

28 Feb 2018 UTC+8Views:

CHAENG (Great Wall Steel Casting) has over ten years’ experience in manufacturing large steel castings according to customers’ drawings, commented by customers as “professional manufacturer”, “reliable supplier”, “high cost-efficient supplier”.

Girth gear is one of the key products of CHAENG. CHAENG supplies cast steel girth gear with diameter of 2-14m and piece weight of 1-150 tons, for rotary kiln, rotary dryer, ball mill, etc.

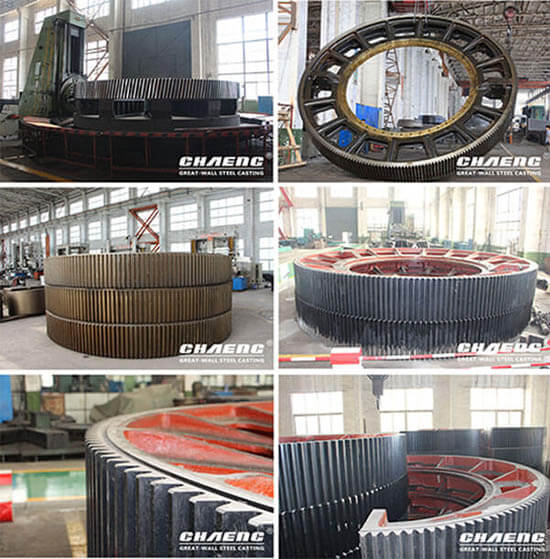

Photos of CHAENG girth gears

CHAENG girth gears with excellent product quality are not only sold throughout China, and also have been successfully exported to foreign markets. For example: CHAENG girth gears are applied to the Xinjiang Tianshan Group, Henan Meng Group, and other well-known domestic and foreign cement enterprises, for the normal operation of ball mill and rotary kiln.

Why so many large enterprises choose CHAENG:

1. Special Heat Treatment Technology

CHAENG adopts special heat treatment technology to optimize structure, improve the hardness and enhance the impact-resistance of girth gear.

2. Long Service Life

CHAENG adopts high strength steel to produce girth gear. Firstly characteristics optimization of rotary kiln is done to guarantee its stability during long time operation, also to prolong its working life.

3. Cost-effective

CHAENG has the advanced casting equipment, strictly follows the national lever-2 detection standards, and executes 360째 all-round nondestructive testing system, to ensure the reliable quality and long service life of steel castings. CHAENG is hailed as "high cost-effective steel castings manufacturer".

4. Fast delivery

CHAENG has strong technical teams, detailed production scheduling, wide range of raw materials purchase channels, and perfect logistics delivery system, making efforts to achieve as fast delivery period as required.