Rolling Mill Housing

Weight : 1~150t

Material : ASTM: 1035 / DIN: CK35

Applicable device: Rolling mill

Application: Metallurgical industry

Customizable : Yes

CHAENG rolling mill parts: rolls for rolling mill, rolling mill housing, rolling mill stand

A mill housing is a large structure that supports the rolls used in the rolling process, and absorbs weight from the process to make the process smooth. It consists of a drive side and work side. A plate moves between the sides to be press rolled. As most of the rolling mills work in a complicated environment, during the working process, heavy shocks will be produced from rollers to the mill housing, which may cause the inside surface and the bottom surface of mill housing into corrosive wear problem in varying degree. Thus, the gap between the rolling mill stand and the roller bearing chock may exceed the limit value that can be controlled. The working condition of main transmit system may also be deteriorated by the extended gap, which increases the transmit system’s vibration shock. The steel ingot will slip while it is biting. Thus the strip shape will also be affect and so does the product quality.

Advertages:

1. Great Wall Steel Casting Company adopt CAE simulation software, to make sure rolling mill housings no shrinkage, no shrinkage, dense, good mechanical properties;

2. Strictly control the quality of molten steel to reduce the harmful gases and element content, improve the purity of liquid steel, thus ensuring the quality of Mill Housing;

3. Adopt a unique heat treatment, greatly enhancing the wear resistance and impact resistance, extending its life;

4. Use high molecular structure material, endows the roll housing with the good performance of impact resistance and less abrasion, the roll housings casted by us are with good performance of corrosion resistance, which protect the surface from the cooling water’s corrosion.

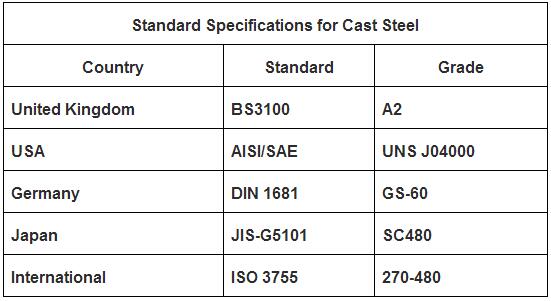

Our main material for the mill housing is similar to followings:

Quality assurance:

The fabrication route of mill housing is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

• Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

• Dimensional check supported with a “as-built“ sketch;

• Record of the heat treatment chart

Our service:

- Prompt response in 24h after your inquiry

- Several years high-precision processing experience

OEM service:

- Advanced management ability with high technology

- Strictly quality control

- We design the production according to your drawing when you supply the design drawing.

Rolling Mill Housing Manufacturing Process:

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Case:

The high quality rolling mill housings produced by Xinxiang Great Wall Steel Casting Co., Ltd are sold to the province of Zhejiang, Shandong, Hebei, Henan, etc. Some of them are favored by many military enterprises.

The mill housing made by CHAENG (Great Wall Steel Casting Co.,Ltd) is used in the rolling mill products of a Shandong Manufacture.

Application:

- Rolling mill

- Rolling tube mill

- Rolling pipe mill