-

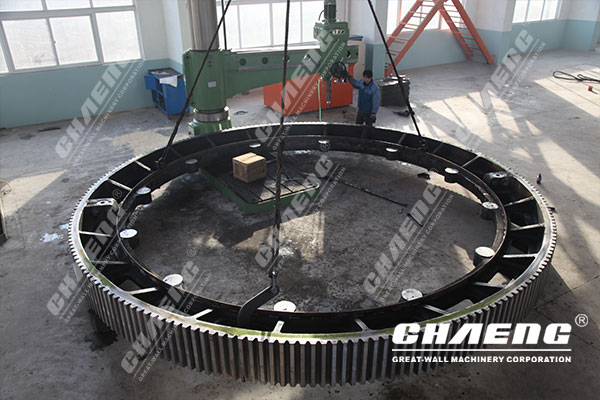

Xinxiang Great Wall in February the latest batch of product shipment diagram

Xinxiang Great Wall in February the latest batch of product shipment diagram

Xinxiang Great Wall in February the latest batch of product shipment diagram

01/31/2024 -

Valve body of inlet ball valve of hydropower station is shipped

Valve body of inlet ball valve of hydropower station is shipped

Valve body of inlet ball valve of hydropower station is shipped

01/26/2024 -

The first batch of slag pots delivery in 2024

The first batch of slag pots delivery in 2024

The first batch of slag pots delivery in 2024

01/19/2024 -

Latest Rotary Kiln tyre and kiln support roller Delivery Picture

Latest Rotary Kiln tyre and kiln support roller Delivery Picture

Latest Rotary Kiln tyre and kiln support roller Delivery Picture

01/12/2024 -

What are the precautions for the repairs of common steel casting parts?

What are the precautions for the repairs of common steel casting parts?

The steel casting part is a component made of cast steel. In the casting steel parts, its performance is similar to that of cast iron, and in use, it is higher than the cast iron.

01/05/2024 -

How to maintain the ball mill head and ball mill trunnion after wear?

How to maintain the ball mill head and ball mill trunnion after wear?

The ball mill head and ball mill trunnion are damaged during use, which will affect the use of ball mill equipment. China large casting steel manufacturers summarize the following points according to the problems that customers often encounter:

12/21/2023 -

What are the reasons for noise when large girth gear working?

What are the reasons for noise when large girth gear working?

At the end of the year, there are many maintenance of cement plants and mining stars. There are many large tooth fengs that need to be replaced. If you need to purchase a large girth gear or other spare parts, please send the drawings to my mailbox contac

12/19/2023 -

What are the materials for large -scale casting steel parts processing manufacturers?

What are the materials for large -scale casting steel parts processing manufacturers?

The foundation of casting materials used in large -scale casting plants in China is that the size of the machine tool has a large casting size, a length of several meters, a mass of more than 10t, and a wall thickness between 15 and 30mm.

12/15/2023