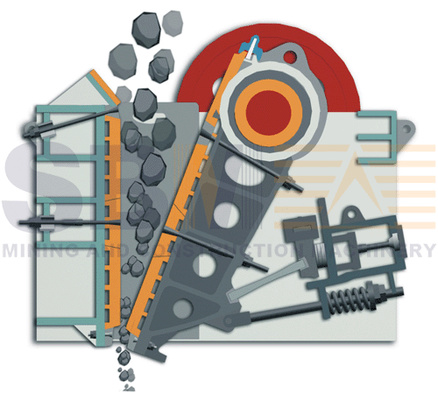

What are the Jaw Crusher Eccentric Shaft Bearings?

Jaw crusher is an important equipment on many mine production lines, There are 4 bearings on the eccentric shaft for jaw crushser: two on each side of the jaw frame supporting the shaft and two at each end of the pitman. These bearings are typically roller in style and usually have labyrinth seals and some are lubricated with an oil bath system. Bearings that support the main shaft. Normally they are spherical tapered roller bearings on an overhead eccentric jaw crusher.

In normal conditions,anti-Friction Bearings are heavy duty double row self-aligned roller-bearings mounted in the frame and pitmans are properly protected against the ingress of dust and any foreign matter by carefully machined labyrinth seals. Crushing Jaws are castings of austenitic manganese steel conforming to IS 276 grade I & II. The real faces of the crushing jaws are leveled by surface grinding in order to ensure that they fit snugly on the crusher frame and jaw stock. The crushing jaws are reversible to ensure uniform wear and tear of grooves.(sometimes implemented and a more adjustable or hydraulic fashion) allow for this adjustment.