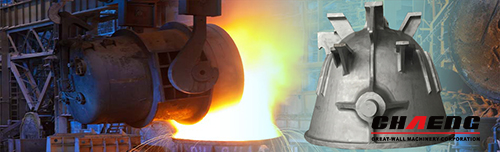

Where is the future development direction of cast steel industry

Here is a look at some of our most recent environmental initiatives.

In 2010, Great Wall Steel Casting Company Steel installed a new thermal reclamation system into the foundry. Our combined reclamation process of both thermal and mechanical (the shakeout system) processes has allowed us to reuse 80% of the sand in our facility. This cuts down on waste and requires us to purchase smaller amounts of new sand for molding and casting.

We recently installed a new dust collector rated at 40,000 cubic feet per minute. This keeps our facility"s air cleaner and our equipment running smoothly.

As part of Earth Day initiatives in 2012, Great Wall Steel Casting Company launched two new projects. The facility now has a recycling program with bins for paper, plastic, and aluminum cans. Our departments also got into the “green” spirit by using recycled wood pallets to make garden boxes which line the front of our building.

As required by OSHA and the EPA, Great Wall Steel Casting Company Steel completes air and water testing on a monthly basis.

Every employee is required to go through safety, health, and environmental training.

Foundries have a long history when it came to environmental sustainability and advocacy. Through the use of new, state-of-the-art technology and engineering, Great Wall Steel Casting Company Steel has become an important environmental steward in the Quad Cities, and an advocate for “greener” initiatives in the casting and machining industries.

At Great Wall Steel Casting Company, being “green” has not just impacted our environment positively – it haszhelped us keep costs down, too. By reusing and recycling materials, we have purchased less of the necessary casting steel supplies like sand.