The grinding roller materials of cement vertical roller mill impact on its quality

Cement vertical roller mill on account of its obvious energy saving characteristic is widely used, but vertical mill grinding roller and disc wear problems have forced the owners headaches. Irregular wear parts, plus that due to abrasion so that the gap between the roller and the disc increase,to decrease operating efficiency equipment, energy consumption continues to increase, these problems eventually led to the roller mill shutdowns. Thus, one of the important topics to improve the cement vertical roller mill and disc wear resistance will become a large enterprise of research.

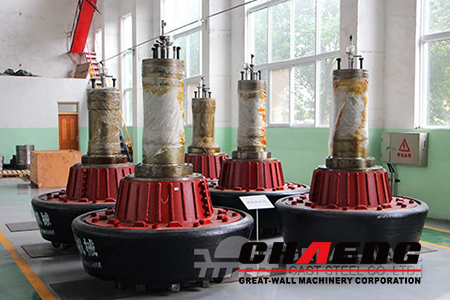

Great Wall steel casting company is a professional large-scale domestic steel casting foundry,has many years of experience in casting large steel castings, in vertical mill roller foundry, Great Wall Steel Casting Company has a unique advantage that has made it a world-class vertical mill manufacturers - Denmark Smith vertical roller mill suppliers. On how to improve the performance of vertical roller mill,Great Wall steel casting company decides from vertical roller mill grinding materials and casting process to adjust.

Great Wall steel casting company choose high strength alloy steel casting, high production of roller hardness, cracking good wear resistance; Not only that,Great Wall Steel Casting company has strict production standards, and throughout the design, production, management, all aspects of marketing, and service; the strict quality control and first-class testing level, to further ensure the vertical roller mill internal quality,to extend the service life of vertical roller mill.