Operating Conditions of cement Ball Mill

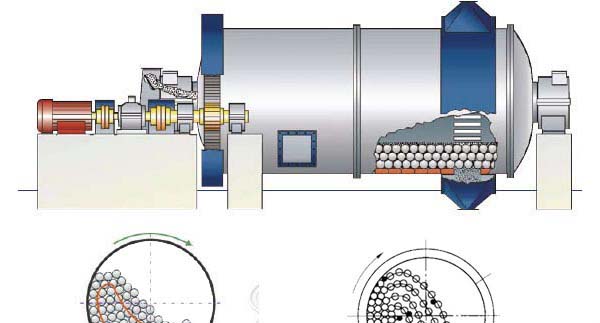

1. The rate of the rotate and the filling. When the filling rate is 30% to 50%, and the rotate rate is 40% to 80%, the useful rate of the machine will increase with the increase of the rotate rate. Thus when the rotate rate gets to a proper number, the productivity of the ball mill will get the top rate as well as the filling rate reaching 40% to 50%.

2.The shape and size of the ball mill. Except steel ball and steel bar, the shape of the grinding medium also includes steel short column and steel column ball,which have more effect than the steel ball and bar. Thus some iron dressing plant have adopted abnormity grinding medium instead of steel ball in the second section of milling operation.

3. The density of the pulp and the speed of the feeding ore into ball mill trunnion. Pulp density has its best range. The feeding speed should be equality and continuity. If not, such as too little feeding ore, which will excess the wear of the machine. On the contrary, bulging belly will happens and stop production when necessary.

4.Cyclic load. Typically,the appropriate value of the cyclic load id 150% to 600%.