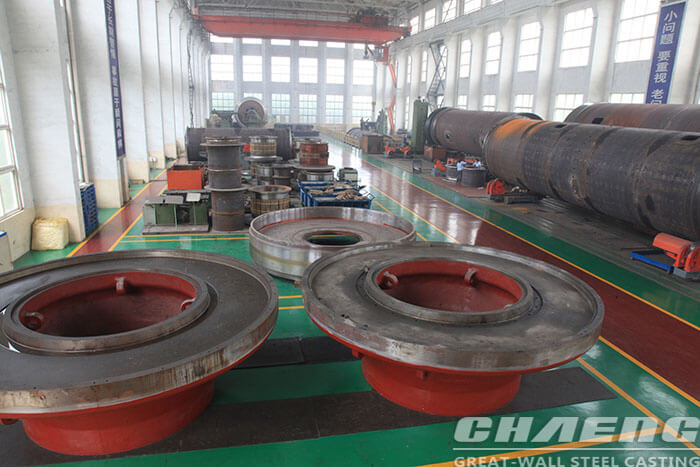

Vertical mill grinding roller manufacturer CHAENG - Casting grinding roller

29 Sep 2018 UTC+8Views:

The grinding roller is an important part of the vertical mill to grind materials. Therefore, during the operation of the vertical mill, the grinding roller will suffer wears, which means that every spare part has its service life. For customers, choosing grinding roller with long service life is a guarantee for the long-term normal operation of the vertical mill.

The surfacing welding advantages of CHAENG vertical mill grinding roller are:

1. the surface is flat, the weld bead is beautiful.

2, the surface hardness of the roller can reach HRC56-60.

3. The weld layer has uniform transverse lines to release the internal stress of the weld.

4. The service life is increased by 2 times.

CHAENG introduces advanced foreign surfacing technology, optimized the arc welding process. The grinding roller and the grinding table are all welded with German imported welding wire, which effectively guarantees the service life of the grinding roller and the production efficiency of vertical mill, and reduces the surfacing frequency, to significantly saves maintenance costs and also avoid production losses caused by maintenance shutdowns. In addition to the good achievements in the field of surfacing welding, CHAENG is also fruitful in the manufacture of grinding rollers and other large steel castings such as grinding table, grinding roller hub and rocker arms.

Welcome to consult us for vertical roller mill spare parts!

Email: casting@chaeng.co

Tel.:86-371-55019878