Focusing on the slag pot manufacturing for 12 years, CHAENG has mature manufacturing technology and rich experience to provide high-quality slag pots for world metallurgical companies. CHAENG has long-term cooperation with many world well-known steel companies like Baosteel, Mittal, TaTa, POSCO, etc.

More than 50 types of and more than 1000 pieces of CHAENG slag pots are exported to countries and areas around the world: the United States, Germany, Italy, India, Japan, Canada, South Africa, Belgium, Korea, Chile, Mexico, etc. We have accumulated rich experience and manufacturing technology of the slag pots for the black metal, non-ferrous metal, the lead smelting, and so on.

| Importing Countries | Purchasing Date | Name | Quantity / piece |

|---|

| Brazil | July. 19, 2008 | Slag pot | 1 Quantity / pie |

| Korea’s posco | Dec. 12, 2008 | Slag pot | 13 |

| Mittal in USA | Dec. 2009 – Feb. 2016 | Slag pot | 15 |

| Mittal in USA | Mar. 2010 – Feb. 2012 | Slag pot | 10 |

| Hengyang | April.2010 | Slag pot | 2 |

| Chiba in Japan | May. 2010 | Slag pot | 4 |

| Mittal in USA | Aug. 2010 | Slag pot | 4 |

| Mexico | Nov. 2010 – Sep. 2015 | Slag pot | 6 |

| Mittal in USA | Nov. 2010 – Sep. 2015 | Slag pot | 4 |

| Mittal in USA | Feb. 2011 – Oct.2015 | Slag pot | 19 |

| Bafang Copper industry | Mar. 2011 | Slag pot | 20 |

| Mittal in USA | June. 2011 – Mar. 2012 | Slag pot | 4 |

| Posco in Zhangjiajie | July. 2011 | Slag pot | 6 |

| Qinhuangdao | Sep. 2011 | Slag pot | 2 |

| Mittal in USA | Dec. 2011 | Slag pot | 4 |

| Mittal in USA | Feb. 2012-0ct.2015 | Slag pot | 13 |

| Germany | Feb. 2012 | Slag pot | 5 |

| Mittal in USA | July. 2012 – Dec, 2016 | Slag pot | 12 |

| Germany | July. 2012 | Slag pot | 2 |

| Mittal in USA | Oct. 2012 – Oct. 2014 | Slag pot | 7 |

| Chicago | Oct. 2012 – June. 2015 | Slag pot | 14 |

| TATA in India | Mar. 2013 – June. 2016 | Slag pot | 5 |

| Mittal in USA | Mar. 2013 | Slag pot | 2 |

| Mittal in USA | April. 2013 | Slag pot | 1 |

| Germany | April. 2013 | Pouring ladle | 3 |

| Germany | April. 2013 | Slag pot | 2 |

| Germany | April. 2013 | Slag pot | 6 |

| Germany | June. 2013 | Pouring ladle | 5 |

| Germany | June. 2013 | Slag pot | 1 |

| Germany | June. 2013 | Slag pot | 5 |

| Germany | June. 2013 | Slag pot | 6 |

| Mexico | June. 2013 | Slag pot | 1 |

| Mittal in USA | June. 2013 | Slag pot | 1 |

| Mittal in USA | July. 2013 | Slag pot | 3 |

| Germany | Aug. 2013 | Slag pot | 2 |

| Germany | Aug. 2013 | Slag pot | 1 |

| Germany | Sep. 2013 – Sep. 2014 | Pouring ladle | 6 |

| Germany | Sep. 2013 | Slag pot | 4 |

| Germany | Sep. 2013 | Slag pot | 8 |

| Germany | Sep. 2013 – Sep. 2014 | Slag pot | 10 |

| Germany | Nov. 2013 | Pouring ladle | 1 |

| Germany | Feb. 2014 | Pouring ladle | 5 |

| Germany | April. 2014 | Pouring ladle | 2 |

| Germany | April. 2014 | Pouring ladle | 6 |

| Germany | June. 2014 | Pouring ladle | 1 |

| Germany | June. 2014 | Pouring ladle | 6 |

| Germany | June. 2014 | Pouring ladle | 2 |

| Germany | July. 2014 | Pouring ladle | 2 |

| Germany | Aug. 2014 | Pouring ladle | 2 |

| Mexico | May. 2014 – Mar. 2015 | Slag pot | 6 |

| Mittal in Africa | Sep. 2014 – Aug. 2016 | Slag pot | 11 |

| Germany | Sep. 2014 | Slag pot | 2 |

| Germany | Oct. 2014 | Pouring ladle | 1 |

| Germany | Oct. 2014 | Pouring ladle | 1 |

| Germany | Oct. 2014 | Pouring ladle | 2 |

| Mittal in USA | Oct. 2014 | Slag pot | 3 |

| Germany | Oct. 2014 | Pouring ladle | 4 |

| India | Nov. 2014 | Slag pot | 4 |

| Belgium | Dec. 2014 | Slag pot | 2 |

| Germany | Mar. 2015 | Pouring ladle | 1 |

| Belgium | Mar. 2015 | Slag pot | 1 |

| Finland | April. 2015 - Nov. 2016 | Slag pot | 26 |

| Germany | May. 2015 – Mar. 2016 | Pouring ladle | 18 |

| Germany | June. 2015 | Pouring ladle | 2 |

| Germany | June. 2015 | Pouring ladle | 1 |

| Germany | July. 2015 | Pouring ladle | 3 |

| Germany | July. 2015 | Pouring ladle | 2 |

| Germany | July. 2015 | Pouring ladle | 2 |

| Mittal in USA | July. 2015 | Slag pot | 2 |

| Germany | Sep. 2015 | Rope wheel | 1 |

| Germany | Oct. 2015 | Pouring ladle | 1 |

| Chicago | Oct. 2015 – Dec. 2016 | Slag pot | 3 |

| Germany | Nov. 2015 | Pouring ladle | 1 |

| Germany | Nov. 2015 | Pouring ladle | 1 |

| Germany | Dec. 2015 | Pouring ladle | 1 |

| Mittal in USA | Jan. 2016 | Pouring ladle | 2 |

| Germany | Mar. 2016 | Pouring gate | 1 |

| Germany | Mar. 2016 | Pouring ladle | 1 |

| Germany | Mar. 2016 | Pouring ladle | 1 |

| Chicago | April. 2016 | Slag pot | 2 |

| Germany | June. 2016 | Pouring ladle | 6 |

| Germany | June. 2016 | Pouring ladle | 2 |

| Japan | June. 2016 | Slag pot | 6 |

| Mittal in USA | Aug. 2016 | Pouring ladle | 2 |

| South Africa | Sep. 2016 | Slag pot | 2 |

| South Africa | Sep. 2016 | Slag pot | 2 |

| Germany | Oct. 2016 | Pouring ladle | 4 |

| Germany | Oct. 2016 | Pouring ladle | 4 |

| Germany | Nov. 2016 | Pouring ladle | 12 |

| Germany | Nov. 2016 | Pouring ladle | 4 |

| Germany | Dec. 2016 | Pouring ladle | 2 |

| Germany | Dec. 2016 | Pouring ladle | 1 |

| Germany | Dec. 2016 | Pouring ladle | 4 |

| South Africa | March-May, 2017 | Slag Pot | 3 |

| Indonesia | June, 2017 | Slag Pot | 1 |

| South Africa | March, 2018 | Slag Pot | 2 |

| West Asia | April, 2019 | Slag Pot | 2 |

| USA | 2019-2021 | Slag Pot | 72 |

| India | 2020-2021 | Slag Pot | 6 |

| Australia | 2020 | Slag Pot | 2 |

| Austria | 2019-2021 | Slag Pot | 36 |

| Germany | 2018-2021 | Slag Pot | 147 |

| Europe | 2019-2021 | Slag Pot | 41 |

| Colombia | 2020 | Slag Pot | 1 |

| Canada | 2020 | Slag pot | 5 |

| Mexico | 2020 | Slag Pot | 1 |

| South Africa | 2019-2021 | Slag Pot | 12 |

| Japan | 2019-2021 | Slag Pot | 13 |

| France | 2022 | Slag Pot | 2 |

| India | 2022 | Slag Pot | 7 |

| Belgium | 2022 | Slag Pot | 2 |

| South Africa | 2022 | Slag Pot | 2 |

| Colombia | 2022 | Slag Pot | 1 |

The service life of CHAENG slag pots is 20% longer than that of the counterparts on the market, and the first repair time is delayed by 2-3 months. (Ps: The life of the slag pot is directly related to the use environment and frequency of use)

CHAENG uses advanced flaw detection equipment to perform non-destructive flaw detection on each slag pot to ensure the internal quality of the slag pot. Ultrasonic testing (UT) of key parts can reach the level 2 flaw detection standard of GB7233-2007, or CHAENG also can design the process according to the customer’s specific flaw detection standard.

With more than 10 years of experience in slag pot casting, CHAENG has formed a strong technical team, detailed production schedules, wide raw material purchase channels, and a complete logistics delivery system, which greatly shortened the delivery time.

CHAENG is the member of China Foundry Association, professionally providing various specifications of slag pot processing services for many years. Its rich experience, powerful production equipment, professional machining and flaw detection, lay the foundation for the production of high-quality castings.

CHAENG follows the national level 2 flaw detection standards, and implements a comprehensive non-destructive testing system. CHAENG pass ISO9001: 2015 quality management system certification, environmental management system certification, occupational health and safety management system certification, and safety production standardization certification.

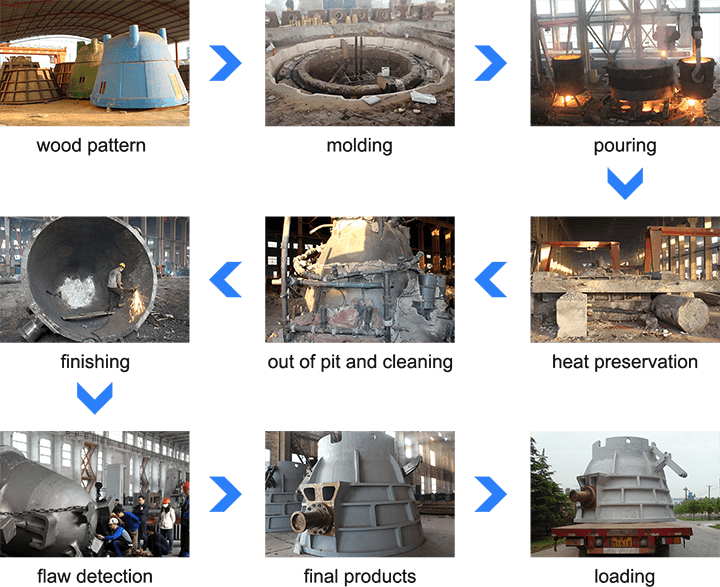

Before production, conduct technical exchanges with customers to formulate specific production plans for slag pots; strictly control each process from die sinking, modeling, pouring, to testing; regularly train first-line operators to ensure the stable production quality of slag pots.

According to your different requirements